Properly chosen product inspection can significantly reduce the risk of extra costs associated with delivery of defective products to your customers. Almost all parameters of your products can be checked. For example, we can check the completeness of the product, deviations from the required shape, its physical or visual properties, as well as various electrical quantities.

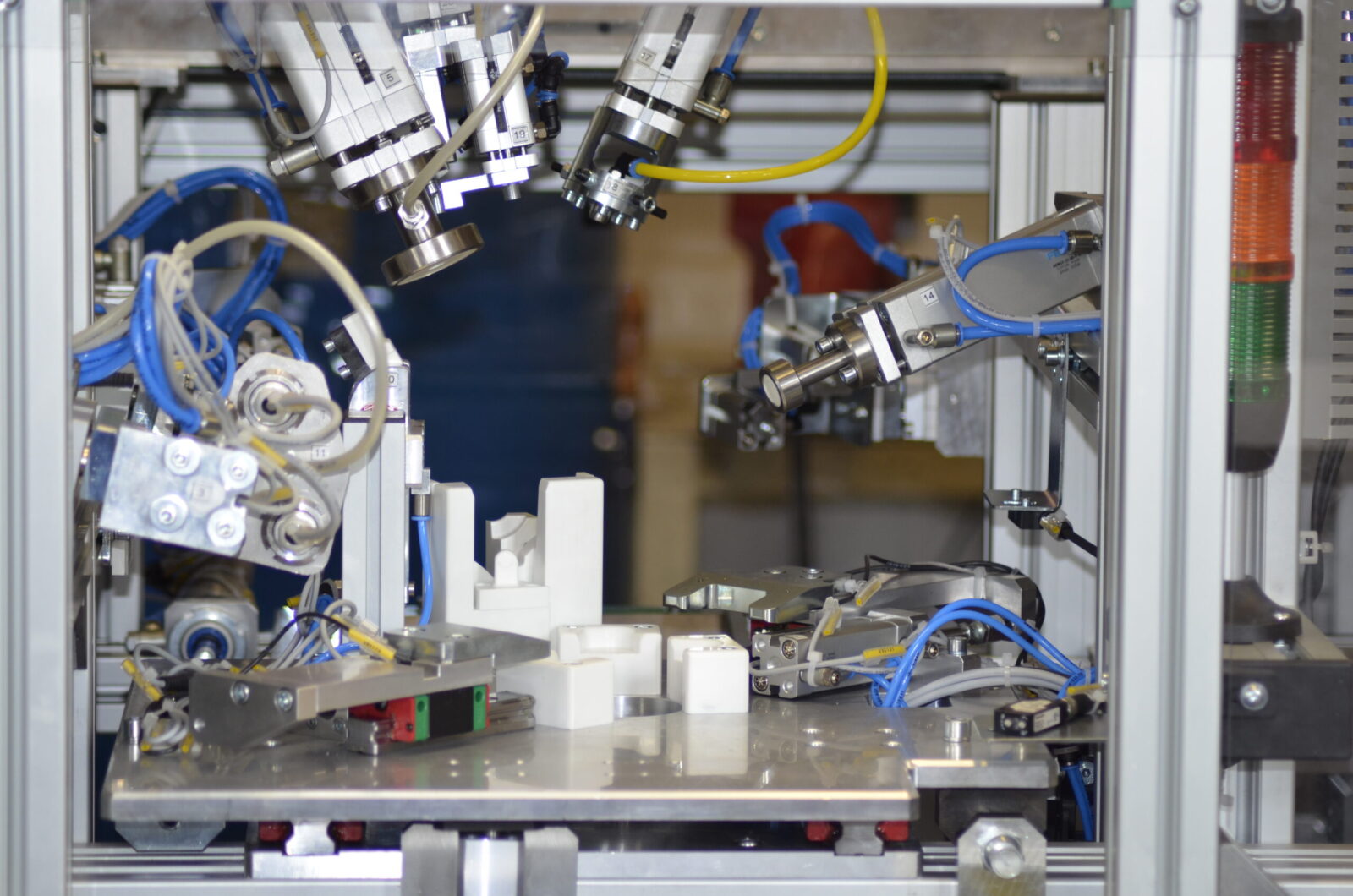

We design the test equipment precisely according to the requirements for the parameters to be inspected. Our testers contain both simple induction or capacitive sensors and basic camera sensors for inspection of a part’s presence, as well as highly sophisticated camera systems with artificial intelligence or top-class devices for inspection of leakage or flow of media.

After the first consultation with you, we will come up with a proposal that respects your requirements for the inspection process. The system functionality will first be verified in our company and then the entire system will be professionally implemented in your production. The result will be a full inspection of your manufacturing process in terms of product quality.

Why should you choose De & Co?

- We guarantee high quality

- Years of experience in product inspection

- Our prices are some of the lowest in the market

- Application of verified and stable inspection mechanisms only

- We provide extraordinary and flexible customer service

Optimization of inspection in your production saves time and money

Delivery of a defective product to the customer is always associated with additional costs and loss of confidence, therefore, it is necessary to have the production process under control and to minimise the possibility of the occurrence of defective products among your OK products. By selecting suitable inspection mechanisms, you can keep your production under full control, and last but not least, you will improve your credibility with your customers.

To be stable, every process must be under control. Therefore, if you want to save time, energy and money that you would otherwise spend on remedying problems associated with production and supply of nonconforming products, invest primarily in appropriate inspection mechanisms. The result will always be higher and reliable production efficiency without undesired extra costs, and you will have your process under control.

How will our cooperation take place?

Send us your enquiry, describing what parameters of your products you want to inspect.

Based on joint meetings and consultations, we will approve the proposal of the inspection station and then will prepare a quotation.

Once the purchase order has been placed, the equipment is designed. Once you have approved the 3D model of the station, it is manufactured, assembled and its functionality tested in our premises.

The equipment is installed in your operation, tested and fine-tuned to the required parameters. The operators are properly trained.

We remain in contact with you and are ready to provide you with customer service within 48 hours.

Reference

„We have been cooperating with DE & CO since 2014, when they designed, manufactured and supplied the first simple assembly equipment for our company. Subsequently, when we verified their professionalism and technical standard, they implemented a number of other assembly stations and complete single-purpose lines for us. As far as our cooperation is concerned, I particularly appreciate DE & CO's high level of support and their active approach at all stages of the implementation of the individual projects. And this is not the only thing that made DE & CO one of our leading suppliers of automation and assembly lines.“

Vladimír Zouhar | ITW Pronovia Czech Republic s.r.o. (Project Engineer)