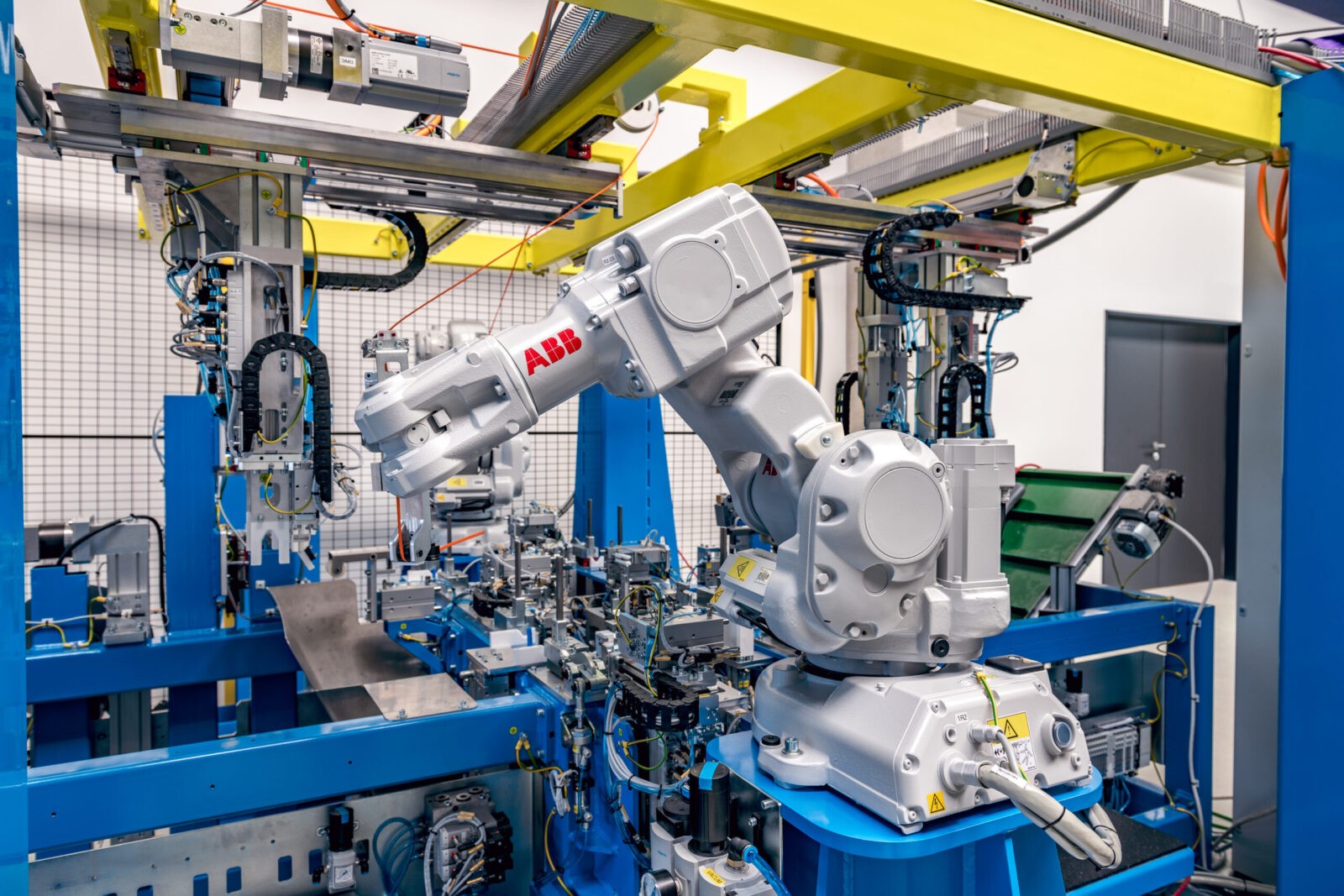

At De & Co, we also have experience in compiling an optimal manufacturing process wherever any type of industrial robot is a part of the station. After the initial consultation with you, we will come up with a proposal that will result in optimisation of your production process in the form of a customised process using an industrial robot.

We use state-of-the-art software to simulate robotic stations – before implementation, we are able to design the entire station in a virtual environment, identify the time demands of production and design it to be as efficient as possible.

Why should you choose De & Co?

- Years of experience in the design of robotised stations

- We use state-of-the-art simulation software

- We have our own robot programmers

- Our prices are some of the lowest in the market

- Close relationships with leading global suppliers of industrial robots

- We provide above-standard flexible customer services

We first propose and verify, then start producing

The first step is a detailed consultation with the client in order to find out exactly what their requirements are and what they would like to change in production. Thanks to our state-of-the-art simulation software, we are able to design the entire production which will include an industrial robot, so that it is as efficient as possible. And once we are 100% convinced that everything has been designed properly, we start the implementation.

How will our cooperation take place?

Send us your enquiry, describing what type of production process you need to optimize.

On the basis of joint meetings and consultations, we will agree on the exact specification of your enquiry and will generate a quotation for you.

Once the purchase order has been placed, the prototype is designed. Once you have approved the 3D model of the station, production and assembly follows which is completed by operational tests of the station in our company premises.

The robotised workplace is installed, tested and commissioned at its destination. The operators are properly trained.

We remain in contact with you and are ready to provide you with the customer service within 48 hours.

Reference

„With DE & CO, we enquired about our largest automation system so far - a packaging line consisting of carton folder, central belt conveyor, part loading containers, 4 handling robots, automatic gluing, labelling and date printing. Already during the RFQ process, it was clear that DE & CO had been dealing with automation for a long time and has a great deal of insight into the issue. In the end, we actually implemented the project together. I appreciate both the professional work throughout the project (design engineering, production, assembly, tuning, etc.) and the approach to solving unexpected problems. We have always been able to agree and find common ground. The work carried out by DE & CO made such an impression on our management that we will implement another, even larger project with them.“

Martin Kozmík | greiner assistec s.r.o. (Technical Manager)